The Basics of Differential Pressure Sensors

The Basics of Differential Pressure Sensors

Introduction

Differential pressure sensors are built to withstand widespread heavy temperature conditions in diverse environmental settings. Utilized in applications such as filter monitoring, gas and oil processing, water, and wastewater, these sensors are reliable and adaptable with cutting-edge precision for challenging conditions. PMC-STS, Inc. offers modern product designs suited for monitoring operational accuracy and optimizing process efficiency while adhering to safety standards in monitoring and testing applications.

What is a Differential Pressure Sensor?

Differential pressure sensors are utilized to measure the pressure difference between two points.

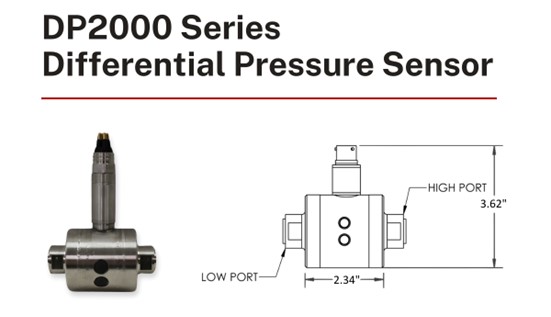

In the following diagram of PMC’s DP2000 transmitter, the two ports measure low/negative pressure and high/positive pressure.

A differential pressure transmitter that can be utilized to calculate pressure measurements is PMC’s DP2000 Series Differential Pressure Transmitter. The DP2000 Series can be utilized to measure flow and efficiency and possesses importance to the test and measurement industry with its hi-line and proof pressure capability.

How Are Differential Pressure Sensors Utilized?

Every differential pressure sensor is utilized differently. Differential pressure sensors use piezoresistive technology to detect the changes of pressure in each port of the sensor. When pressure changes, it deflects a diaphragm in each port. The change in deflection is picked up by the piezoresistive technology and then translated to an output that can be monitored in either milliamps, millivolts, or volts. There are a variety of applications where a differential pressure sensor can be applicable.

DP-EL Differential Pressure Sensor for Filtering Applications

The DP/EL Differential Pressure Transmitter is designed to measure pressure across filter elements. The sensor utilizes the PMC flush-mount diaphragm on the positive pressure side and a 1/8" NPT nipple for the reference pressure side. It is well suited for measuring pressure drop across a line of filter elements.

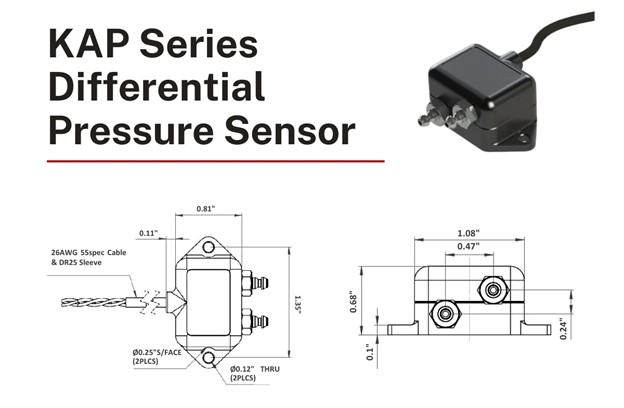

KAP Differential Pressure Sensor for Automotive Testing Applications

The KAP Series Differential Pressure Transducer possesses the capability to measure pressure for on-vehicle automotive applications with the utilization of the KAPT pitot tube. These sensors are ideal for data acquisition or control systems and can be installed directly onto vehicles or as a part of a test stand or dyno. The KAP Series sensor is reliable and protects against high vibration, shock, and high temperatures in motorsport applications.

Conclusion

Differential pressure sensors are a great component in measuring the pressure difference between two points. From filters to motorsports, these sensors are reliable in a variety of applications. Take control of pressure accuracy and measurements today with sensor products from PMC-STS, Inc.